Custom Interconnect Solutions for Aerospace Applications

A wide variety of critically important components go into keeping aviation platforms and equipment operational and airborne. While major subsystems like propulsion and navigation are among the best-known, no aircraft can remain mission-ready without the interconnect components needed to link its equipment together in a single, effective system.

Ferrari Interconnect Solutions has produced products and systems to meet this need for both the aerospace and defence industry since its inception in 2014. Today, as a partner of Ex-Eltronics, this interconnect solutions company offers an extensive range of products and services to support the use of avionics, launchers, communications, flight gear & helmets, test equipment, and many other important assets and supplemental systems.

In this article, we will have a look at what Ferrari Interconnect Systems offers to its customer base today and how this partnership enables Ex-Eltronics to provide total support for similar systems to its ever-growing customer base.

Interconnect Solutions Defined

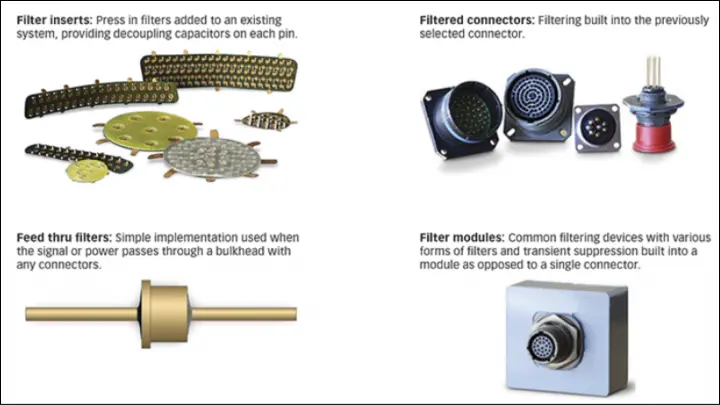

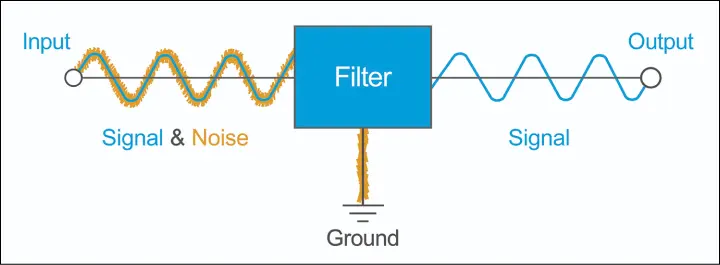

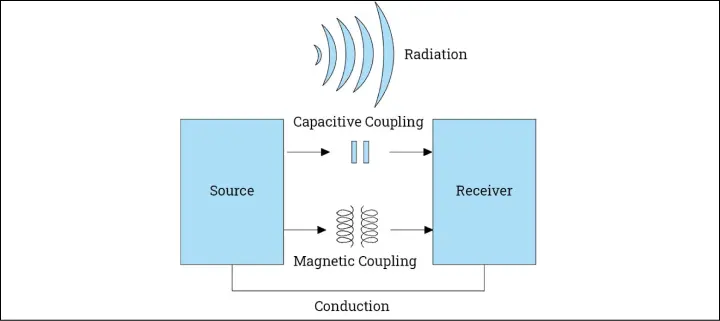

Interconnect solutions refer to products and technologies used to connect different parts of an electrical or electronic system. They’re a key component in enabling communication and data transfer between circuit boards, electronic devices, and systems. Interconnect solutions encompass a wide range of components that include cables, connectors, switches, adapters, sockets, and more.

These solutions come in various forms based on their application; for instance, they can be high-speed data connections in avionics and navigation suites, power connectors in engines, or complex cable assemblies in control and communication systems. They play a crucial role in numerous sectors, including telecommunications, aerospace, critical electronics, and first responders, to name a few.

A custom interconnect solution, as offered by Ferrari, ensures a reliable and robust connection, leading to efficient and high-performance operation of the overall system.

Meet Ferrari Interconnect Solutions

Ferrari Interconnect Solutions (FIS) is a company specialising in providing custom cable and wire products and total interconnect solutions used within avionics and pilot-helmet communications systems. Based in Ontario, California, FIS has been committed to delivering high-quality products and services since its inception in 2014, backed by quality certifications such as ISO 9001 and AS9100.

The experts at FIS pride themselves on their capabilities to produce everything from standardised military equipment to complex custom designs and have experience in this sector dating back to 1978.

Being able to provide rapid turnaround on prototype production, short lead times, and a customer-focused approach gives Ferrari a clear competitive edge. Each product is guaranteed to meet or exceed industry standards, meaning clients can always rely on Ferrari Interconnect Systems for reliable, robust, and efficient solutions.

What FIS Offers

Ferrari Interconnect Solutions specialises in the design, manufacture, and integration of interconnect solutions for use with aircraft communication systems and avionics equipment. Additionally, they offer bespoke design services for custom mil/aero flight applications as well as support for co-opted designs and build-to-print applications for flight, non-flight, and ground-based equipment.

Some of their products include:

- Pilot and tactical helmet comms system and CEP transition cables

- Avionics Box Organized and Ruggedized Wiring

- Launch system Interface Cables

- EMC and CBRN-compatible cable-harness solutions

- Weight-sensitive and Hi-Flex cable-harness systems

- Build-to-print and co-opted wired systems

- Bespoke cable systems designs

- Overmolded cable assemblies

- Breakout and coil cable assemblies

- Braided metal and textile harnesses

- Inline cable electronics (switches, resistors, and diodes)

In addition to these products, FIS offers a wide variety of customary and value-added services, including:

- Design, prototype production, and product validation

- 3D modelling

- Box fabrication

- Electromechanical assembly

- Customer product evaluation

- First Article/AS9102 Inspection

- Electrical and functional Testing

Drawing on extensive experience in design and manufacturing for the aerospace and defence sector, FIS is one of the most capable providers of custom interconnect solutions. Based on customers’ connector interface and environmental requirements, as well as specific performance criteria, their engineering team can produce reliable, innovative designs subject to extensive quality control and performance testing prior to implementation and delivery.

In addition, their experts will furnish clients with supplemental producibility and reliability reviews and feedback at no additional cost for customers’ drawings or designs. Plus, FIS can provide custom packaging and supplementary materials including detailed manuals and operation instructions, shortening the implementation time for newly made products and solutions once they reach customers.

Ex-Eltronics & FIS: Partners in Supplying Top-Tier Interconnect Solutions

Ferrari Interconnect Solutions built its reputation for highly adaptable, robust interconnect solutions in the United States, but its products have almost limitless applicability to avionics and comms systems the world over. International organisations interested in acquiring the services of this interconnect solutions company can turn to Ex-Eltronics, the only official distributor of Ferrari products outside of the US.

If you want to learn more about FIS’ extensive range of products and services or to discuss how they can meet your custom design needs, head over to their partner page on our website to learn more. Or, get in touch today to speak with a helpful representative about how Ex-Eltronics and Ferrari Interconnect Solutions can provide the custom interconnect solutions you need.We can also be reached at [email protected] / +44 (0) 1420 590390