The War on EMI: Filtering v Shielding

Whether you work in defence, aerospace, or industrial environments, electromagnetic interference is a bane to your operations. But what’s the best way to deal with it?

In simple terms, electromagnetic interference (EMI) refers to the effects of electromagnetic fields, such as radio frequencies, on sensitive electronic devices and systems. It’s surprisingly widespread and can be severely detrimental to your systems. Fortunately, there are two possible solutions to this issue: filtering and shielding.

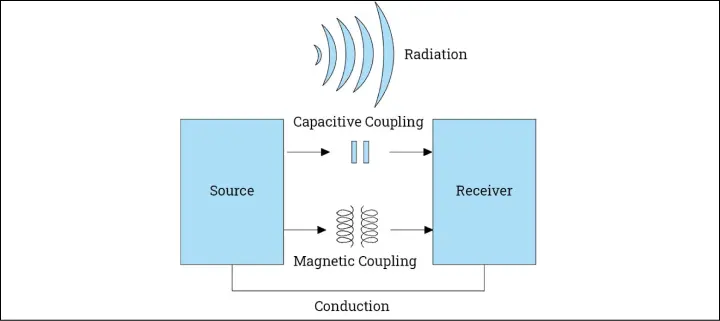

EMI filtering and shielding are two different techniques used to address EMI in electronic devices or systems. With electronic systems, there are concerns regarding radiated and conducted susceptibility AS WELL AS radiated and conducted emissions, which are EMI noise coming from your own system.

But what’s the difference? Read on for more details on the pros and cons of EMI filtering and shielding and what you can do to protect your equipment from radiating or being susceptible to these effects of EMI.

A Brief History of EMI, EMC, and the Need for Protection

By the 1930s, radios were rapidly becoming household essentials across the world, and users began to notice the strange effects the frequencies had on other electronics and electrical devices. The phenomenon, called “electromagnetic interference,” made it clear that a method for protecting devices from errant radio signals was needed. An approach to these issues came in 1933, when the International Special Committee on Radio Interference (CISPR), a sub-committee of the Paris-based International Electrotechnical Commission (IEC), issued the earliest recommendations for minimising EMI. Emissions limitations came about as systems were connected to ensure that noise created in one system would not interfere with the performance of another.

The need for more comprehensive EMI filtering and shielding methods and equipment in defence applications was recognised as early as 1967. That year, the aircraft carrier USS Forrestal, then deployed in the Gulf of Tonkin in support of U.S. forces in Vietnam, suffered a catastrophic fire when an electronic anomaly triggered a Zuni rocket. This led to 134 deaths and nearly 200 injuries. It was later determined that an incorrectly fitted shielded cable connector and multiple electromagnetic fields on the flight deck caused the rocket to fire, igniting a fuel tank on a nearby aircraft.

Later, when mobile phones and other portable electronics became more prevalent in the 1990s, multiple airlines realised that signals from these and other devices could interfere with the avionics suites, hindering an aircraft’s ability to fly or navigate safely. Military leaders found that electromagnetic interference, whether natural or manmade, could disrupt global positioning system technology (GNSS) badly enough that unmanned aerial vehicles could not be reliably flown. GNSS disruption and EMI due to military activity represents a notable civil aviation safety-of-flight concern that continues today.

After radio, many other forms of electromagnetic interference were recognised, including microwaves, infrared, as well as gamma and X-rays, each of which may be countered with an array of methods and devices. CISPR’s recommendations form the basis of modern international EMI prevention standards, as well as define how electronic devices can co-exist without interference affecting performance. This is referred to as electromagnetic compatibility.

Electromagnetic compatibility (EMC) defines the ability of electrical and electronic equipment to operate acceptably when exposed to external electromagnetic sources and limiting internally generated unwanted electromagnetic energy. EMC covers three areas. Limiting EMI emissions generated by the equipment, its susceptibility to external sources of EMI, and its level of immunity when functioning in its defined environment.

Different Types of EMI

Electromagnetic interference can be classified into four general types based on either the source or bandwidth of the original signal. Narrowband EMI is that produced by mobile phones or radio or television transmissions whereas broadband EMI has a wider radio spectrum with unintentional radiation emitted from sources such as electric power transmission lines. Depending on the source, EMI can be classed as intentional, unintentional, intersystem, or intra-system:

- Unintentional, or “non-functional”, EMI is generated by devices not intended to do so, such as welding equipment, DC motors, computers, and power lines.

- Intentional EMI (IEMI) is that emitted by a device specifically designed to do so, typically as part of an electronic warfare system, like electronic countermeasures and electromagnetic pulse (EMP) weapons.

- Intra-system EMI refers to interference generated between two components of a system or device, whereas intersystem EMI occurs between two or more separate systems.

What is EMI Filtering?

EMI filtering is an important consideration in the design and manufacture of electronic devices to ensure their reliable operation and compliance with regulatory requirements for electromagnetic compatibility (EMC).

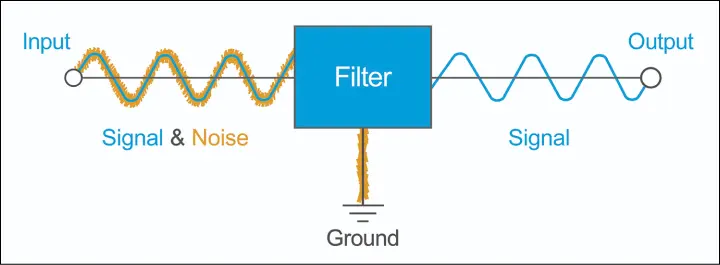

EMI filtering refers to the process of reducing or eliminating the interference caused by electromagnetic signals in electronic devices or systems. It is a technique used to filter out unwanted electromagnetic signals (noise) that can disrupt the operation of electronic devices or cause electromagnetic interference.

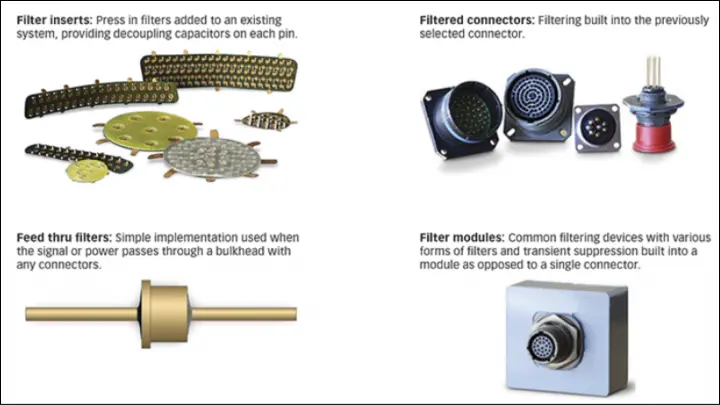

EMI filters are usually placed at the input or output of the device and can be panel-mounted or PCB-mounted. They consist of a combination of passive components such as capacitors, inductors, and resistors, which are designed to attenuate or suppress electromagnetic interference in a given frequency range. They are often used in electronic devices such as power supplies, audio equipment, computer systems, and other electronics that require a high level of reliability and EMC.

EMI filters are typically low-pass filters, which allow lower frequency signals to pass whilst blocking high-frequency signals or ‘noise’. Capacitors block these certain frequencies and allow others through. The capacitors discharge to the ground plane, allowing them to reduce the signal in the higher frequencies. Inductors work differently; they absorb energy from the higher frequencies and turn it into heat, resulting in the dampening of the high-frequency noise. Custom filters can be made by ‘tuning’ the combination of the capacitors and inductors to the specific frequencies required.

EMI filters can be classified into two types: differential mode filters and common mode filters. Differential mode filters attenuate the interference that occurs between two signal lines, while common mode filters attenuate the interference that occurs between a signal line and the ground.

What is EMI Shielding?

EMI shielding is the process of reducing the electromagnetic radiation emitted by electronic devices or systems and also preventing external electromagnetic signals from interfering with the operation of these devices. EMI shielding is necessary because electromagnetic radiation can interfere with the operation of other electronic devices, causing malfunctions or errors. EMI shielding involves the use of conductive materials such as copper or aluminium to block or attenuate electromagnetic signals from entering or leaving the device.

EMI shielding can be achieved by placing a conductive shield around the device (called a Faraday Cage) or by coating the device with a conductive material. The conductive shield or coating creates a barrier that prevents electromagnetic signals from entering or leaving the device, thereby reducing the risk of electromagnetic interference. EMI shielding can be applied to electronic components, circuit boards, cables, and even entire electronic devices or systems.

How Filtering Compares to Shielding

Your choice between filtering and shielding depends on various factors, such as the sensitivity of your device as well as the amount of EMI it will generate. Conductivity, size, and cost will also play a part in choosing the best EMI solution.

Shielding takes a holistic approach to EMI management while filters target specific areas of EMI. As much as shielding reflects incoming energy, some absorption still takes place. Converting into heat energy, this then requires some type of thermal management. Also, the quality of the material used in shielding not only influences the output but the weight of the system as well i.e., thicker shields are more effective but are heavier. And while shielding reflects and cages EMI, filters are capable of eliminating EMI by addressing the most vulnerable points in a system that produce the most interference. As a result, filters may be custom fitted to your specific needs.

Count on Ex-El for All Your EMI Filtering Needs

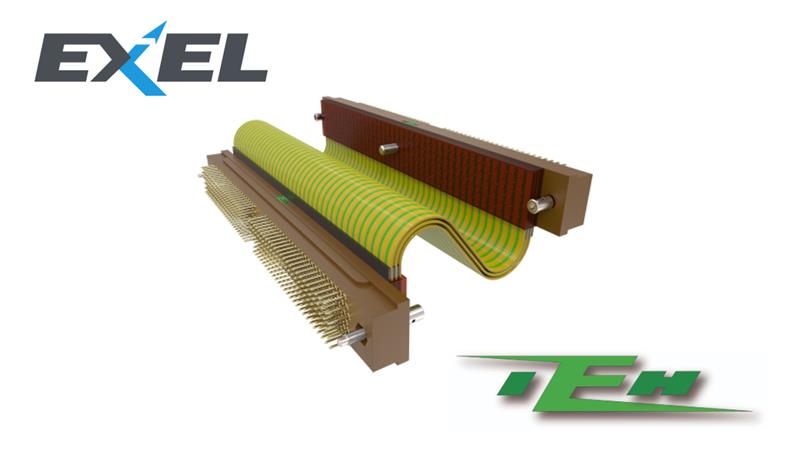

At Ex-El, we have long understood the importance of protecting sensitive industrial and mission-critical military electronics against all forms of electromagnetic interference. That’s why we specialise in the creation of off-the-shelf and custom EMI filtering solutions utilising our partner EMI Solutions.

The EMI filter modules, filtered connectors, and FlexFilter Inserts that we supply to our customers are subjected to the most rigorous testing standards and comply with the highest military and industrial specifications to keep your systems reliable in the most demanding of environments and applications.

We also offer a range of EMC backshells, glands, and panel fittings, which offer 360˚ EMC screening through distribution partnerships. The EMC backshells we supply are UK designed and manufactured, with integral and additional strain relief options as well as environmental sealing options to IP68.

For more information on the products Ex-Eltronics has to offer to see to your EMI needs, visit our partner pages at KEC Limited and Amphenol LTD.

To discuss your needs or to find out more about what we can do for you, reach out to us today.